Automobile Stamping Mould

-

Hot

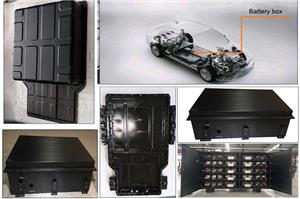

New Energy Battery Pack

The outer shell of the battery pack is made of aluminum, steel or composite materials. The upper and lower shells of the battery pack are hard and not easy to cause physical damage. High and low temperature stability tests have been conducted to ensure safe use.

Send Email Details -

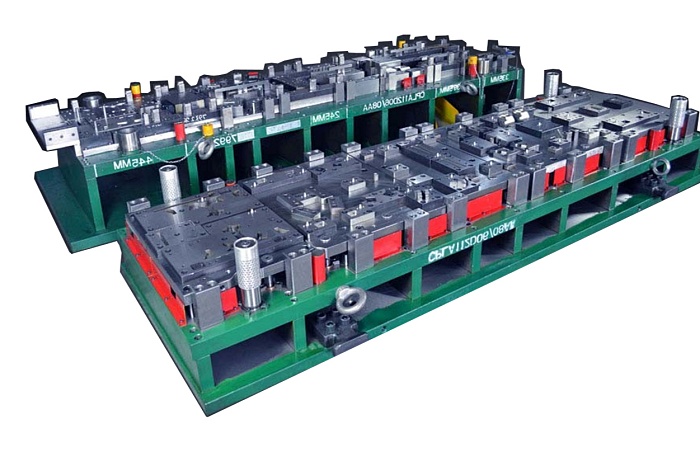

Large Progressive Die

The mold department of the company starts from mold design → CNC material preparation → vacuum heat treatment + grinding → slow and fast wire walking processing → assembly - → mold test. The whole set of processing is completed in the factory, with high efficiency and effective cost reduction.

Send Email Details

We have professional and reasonable production equipment, such as AQ, Ag and other slow wire walking machines, equipped with vacuum heat treatment, CNC and other mold processing equipment, 40-350t stamping machine, 350t oil press, 1-45mm diameter automatic lathe and CNC lathe and other production equipment.

In order to meet the requirements of product quality, our company is equipped with various testing equipment such as three-dimensional element, projector, height gauge, hardness meter, temperature and humidity box, etc. We advocate quality first. -

Hot

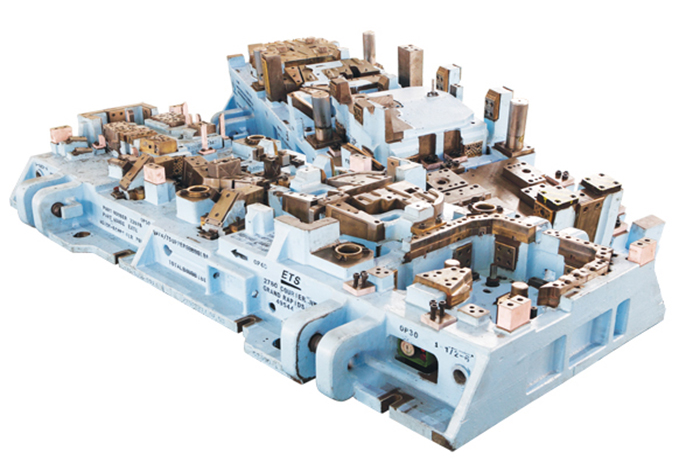

Stamping Automobile Mould

Automotive stamping parts are thick in material, complex in shape, high in safety performance and quality requirements, and difficult to make molds. We have made many kinds of molds for automobile structural parts for domestic and foreign customers. The produced auto parts have been used in the fields of electric vehicles and so on. The mold quality is high, and we can provide high-quality customized molds.

Send Email Details -

Automobile Stamping Die Processing

Automotive stamping parts are thick in material, complex in shape, high in safety performance and quality requirements, and difficult to make molds. We have made many kinds of molds for automobile structural parts for domestic and foreign customers. The produced auto parts have been used in the fields of electric vehicles and so on. The mold quality is high, and we can provide high-quality customized molds.

Send Email Details -

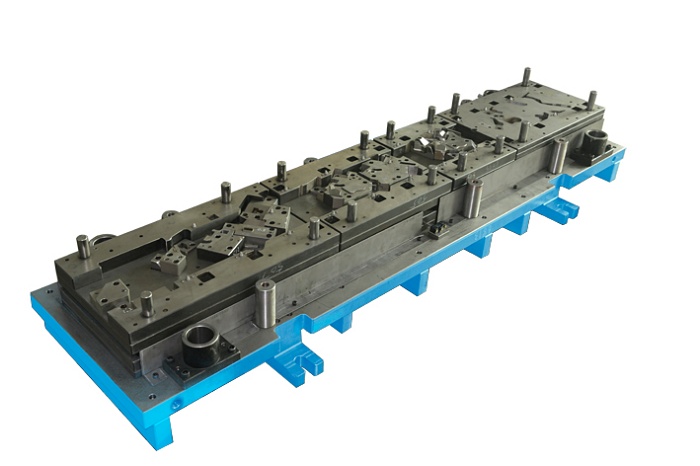

Large Forward Mold

The mold department of the company starts from mold design → CNC material preparation → vacuum heat treatment + grinding → slow and fast wire walking processing → assembly - → mold test. The whole set of processing is completed in the factory, with high efficiency and effective cost reduction.

Send Email Details

We have professional and reasonable production equipment, such as AQ, Ag and other slow wire walking machines, equipped with vacuum heat treatment, CNC and other mold processing equipment, 40-350t stamping machine, 350t oil press, 1-45mm diameter automatic lathe and CNC lathe and other production equipment.

In order to meet the requirements of product quality, our company is equipped with various testing equipment such as three-dimensional element, projector, height gauge, hardness meter, temperature and humidity box, etc. We advocate quality first. -

Automobile Hardware Stamping Mould

Our company has continuously introduced good equipment, and the manufacturing and processing of molds and plastic parts have realized CAD design, CNC milling and three-dimensional inspection, thus ensuring the quality of molds and plastic parts. We manufacture molds and plastic parts: high precision, good quality, short cycle, timely delivery, reasonable price, excellent after-sales service, and strive to serve customers around the world.

Automobile hardware stamping mould Stamping mould for Auto parts Automobile hardware stamping designSend Email Details