Metal Stamping

-

Hot

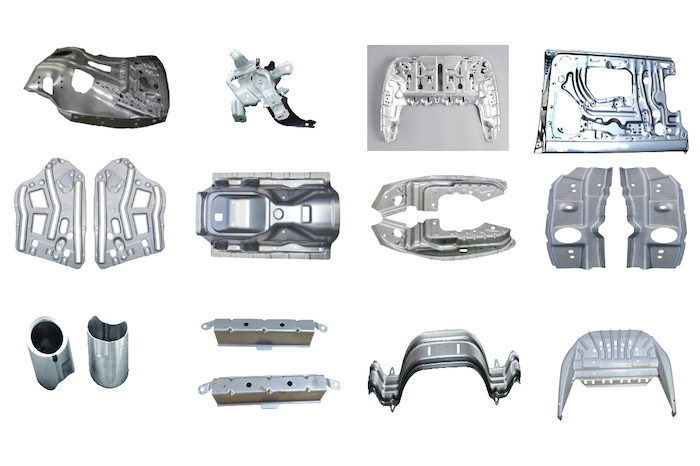

Automotive Metal Stamping Parts

The processing materials we use are stainless steel, aluminum, non-ferrous metals and some alloys. Technology and excellent mold materials, we can minimize the mold parts to achieve the purpose of saving raw materials.

Send Email Details

For some products with high-quality requirements, we can rely on the mold design ability of winlink to realize that the conductive contact parts are free of tool contact marks and burrs, and the insertion and insertion contact of products will be more smooth; Through continuous technical improvement, we can ensure that the contact plane of the manufactured products is free of arc and turnover, so that the conduction of the products will be more stable. -

Metal Stamping Parts

It is made of high-quality materials and suitable for various harsh environments. It is not easy to corrode and rust.

Send Email Details

Can be customized according to customer needs.

Application scope: automobile industry, home appliance industry, medical industry -

Metal Hardware Stamping Parts

The stamping blanks are mainly hot-rolled and cold-rolled steel plates and strips. At present, our factory has a total of 50 small, medium and large punches, as well as several laser cutting machines, which can produce various continuous dies and single punch dies.

Send Email Details -

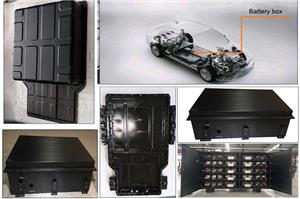

Precision Metal Stamping

The high-speed precision stamping technology is mainly based on the use of sheet metal processing products. It is composed of three basic elements: high-speed press equipment, precision progressive die and high-quality coil material. It is combined into a stamping automatic production line according to the stamping process flow Stamping automation can not only greatly improve labor productivity, improve labor conditions and reduce costs, but also effectively ensure personal safety in stamping production and fundamentally change the production face of stamping

Send Email Details -

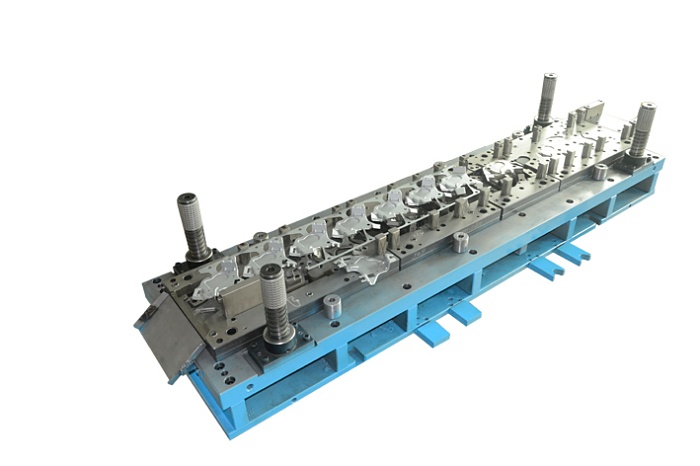

Metal Stamping Mould

80% of the molds are designed on the basis of mold flow analysis

Send Email Details

Has its own mold design, R & D team, 24-hour standby, ready to respond

Mold flow analysis technology, slow wire walking and 200000 turn CNC processing to ensure the quality of precision molds