Precision Mould

-

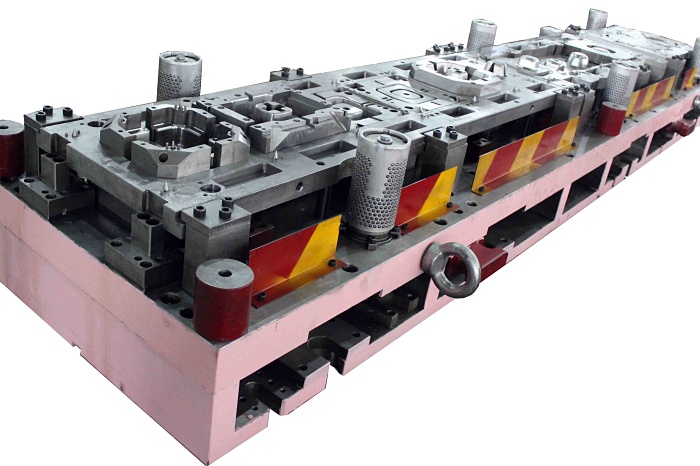

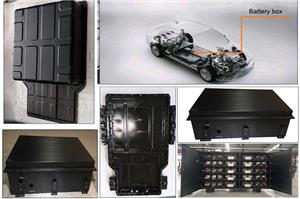

Automobile Precision Mould

Our company is mainly responsible for the stamping process of the whole vehicle parts and the coordination of the whole vehicle molds, and the design and manufacture of the molds for the main parts such as the inner and outer covers of the vehicle body. The manufactured molds include multi station transfer molds, multi station progressive molds (continuous molds), hydroforming molds, metal hot forming molds and prototype molds.

Send Email Details -

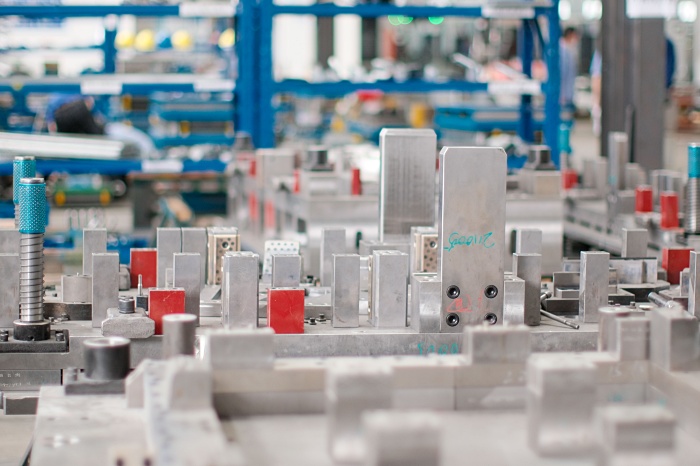

Precision Mold Processing

Mold customization processing flow:

Send Email Details

1. Online consultation

Custom molds need to provide drawings or samples, and we provide quotations through demand.

2. Payment of deposit

If you decide to choose us, you need to pay a deposit first. After we receive the deposit, we will start to split the mold. After the separation, we will arrange the processing of each part and start to make the mold. After the trial production, the deposit will not be returned in any form, except through negotiation between both parties.

3. Confirm the sample

After receiving the sample, the customer confirms that there is no problem with the size and basic shape. After you confirm that the sample is qualified

Pay the remaining balance. If the sample is unqualified, we will modify the mold according to the drawing or the sample (free of charge). If the mold needs to be modified due to the customer's design problem, we will only charge the cost.

4. Product production

After the mold is completed, the customer shall be informed of the mold. After the final payment of the mold is settled (received), we will send out the mold within a week. Customers who need our drawings to pay the mold deposit to draw the drawings (free of charge)

After arriving at the mold, if you need to repair it in the future, you can contact us directly. We are responsible for the repair. No need apply for after-sales on this order. -

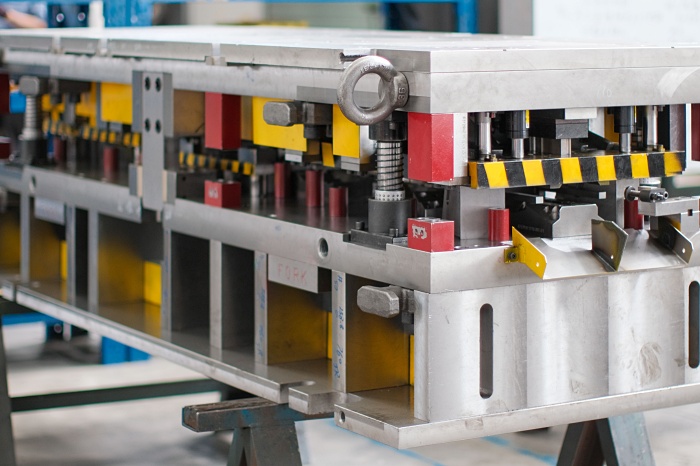

Precision Stamping Mould

Wear resistance

Send Email Details

When the blank is plastically denatured in the mold cavity, it flows and slides along the cavity surface

Make the surface of the cavity and the blank produce violent friction, resulting in the failure of the die due to wear

Therefore, the wear resistance of the material is one of the most basic and important properties of the mold.

Strength and toughness

Most of the working conditions of the molds are very bad, and some often bear large impact loads

Resulting in brittle fracture. In order to prevent sudden brittle fracture of die parts, the die should have high strength and toughness. The toughness of the die mainly depends on the carbon content, grain size and microstructure of the material.

High temperature performance

When the working temperature of the mold is high, the hardness and strength will decrease, leading to the early wear of the mold or plastic deformation and failure. Therefore, the mold material should have high tempering resistance stability to ensure that the mold has high hardness and strength under the working temperature. -

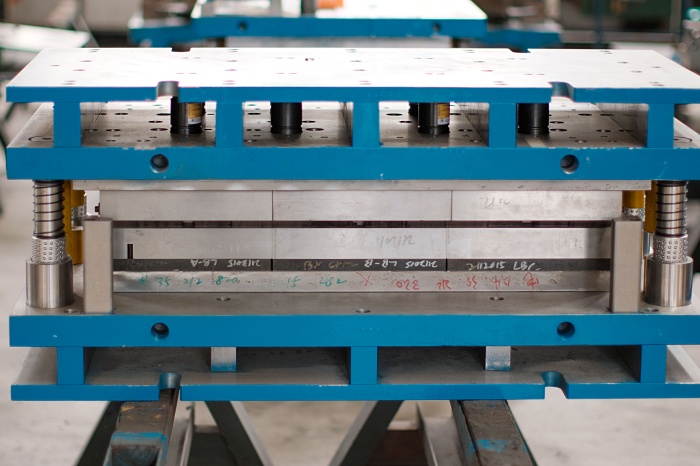

Hardware Precision Mold

Wear resistance

Send Email Details

When the blank is plastically denatured in the mold cavity, it flows and slides along the cavity surface

Make the surface of the cavity and the blank produce violent friction, resulting in the failure of the die due to wear

Therefore, the wear resistance of the material is one of the most basic and important properties of the mold.

Strength and toughness

Most of the working conditions of the molds are very bad, and some often bear large impact loads

Resulting in brittle fracture. In order to prevent sudden brittle fracture of die parts, the die should have high strength and toughness. The toughness of the die mainly depends on the carbon content, grain size and microstructure of the material.

High temperature performance

When the working temperature of the mold is high, the hardness and strength will decrease, leading to the early wear of the mold or plastic deformation and failure. Therefore, the mold material should have high tempering resistance stability to ensure that the mold has high hardness and strength under the working temperature. -

Precision Metal Stamping Mould

Wear resistance

Send Email Details

When the blank is plastically denatured in the mold cavity, it flows and slides along the cavity surface

Make the surface of the cavity and the blank produce violent friction, resulting in the failure of the die due to wear

Therefore, the wear resistance of the material is one of the most basic and important properties of the mold.

Strength and toughness

Most of the working conditions of the molds are very bad, and some often bear large impact loads

Resulting in brittle fracture. In order to prevent sudden brittle fracture of die parts, the die should have high strength and toughness. The toughness of the die mainly depends on the carbon content, grain size and microstructure of the material.

High temperature performance

When the working temperature of the mold is high, the hardness and strength will decrease, leading to the early wear of the mold or plastic deformation and failure. Therefore, the mold material should have high tempering resistance stability to ensure that the mold has high hardness and strength under the working temperature.