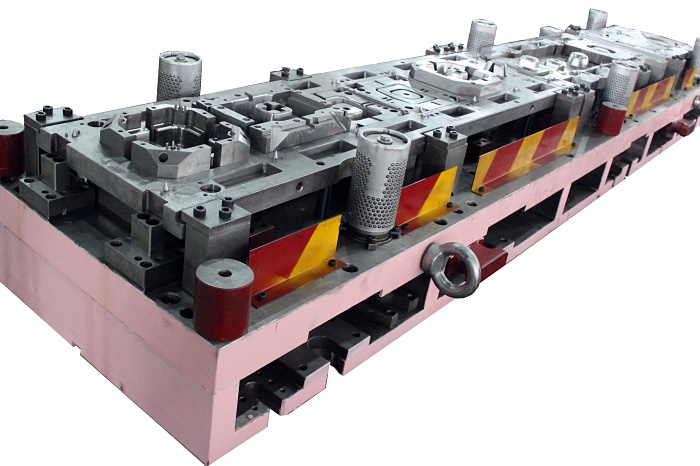

Stamping Mould

-

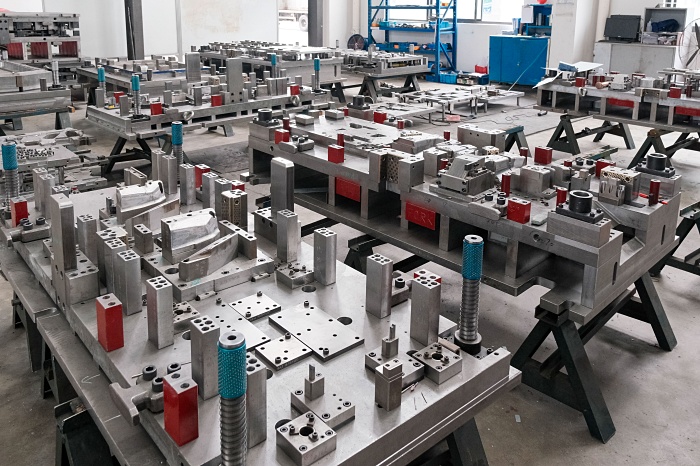

Stamping Mould Processing

Stamping die classification:

Send Email Details

a. Single process die is a die that only completes one stamping process in one stroke of the press.

b. The compound die has only one station. In one stroke of the press, two or more stamping processes are completed at the same station at the same time.

c. Progressive die (also known as continuous die) has two or more stations in the feeding direction of the blank. In one stroke of the press, it is a die that completes two or more stamping processes at different stations one by one.

d. The transfer die integrates the characteristics of single process die and progressive die. By using the manipulator transfer system, the product can be quickly transferred within the die, which can greatly improve the production efficiency of the product, reduce the production cost of the product, save the material cost, and have stable and reliable quality. -

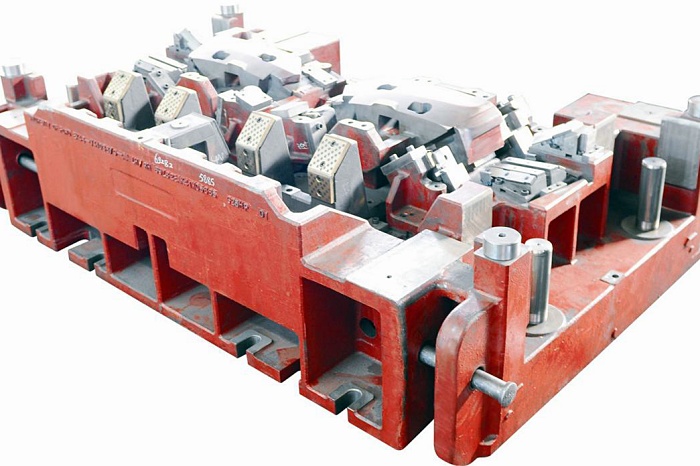

Hot Stamping Mould

In view of the complex production conditions of hot stamping die, hot stamping die steel has the characteristics of high wear resistance, high toughness and high thermal conductivity. In view of the wear resistance and coarsening of the hot stamping die during use, we adopt the ion nitriding treatment technology on the surface of the hot stamping die and the original nitrogen layer adjustment process, which is higher in toughness than the traditional ion nitriding. After ion nitriding, the thickness of white bright layer can reach 8-10 μ m. Nitriding layer thickness: 200-300 μ m. The surface hardness of the die reaches 10000hv, which can significantly improve the roughening problem of the die.

Send Email Details -

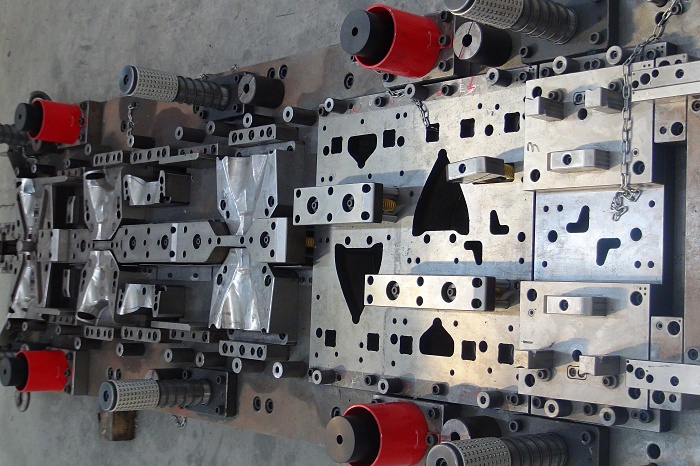

Sheet Metal Stamping Mould

We have large-scale precision CNC and multiple presses to meet the mold test and production needs of various sizes of molds. With high precision, fast processing and accurate molding, we pursue customer satisfaction and help customers achieve exquisite quality. Through the optimization of processing technology and the popularization of automatic programming, the production and processing efficiency is effectively improved. The strict quality control system and high-efficiency working team have rich design experience and mold manufacturing experience.

Send Email Details -

Stamping And Drawing Mould

Stamping die classification:

Send Email Details

a. Single process die is a die that only completes one stamping process in one stroke of the press.

b. The compound die has only one station. In one stroke of the press, two or more stamping processes are completed at the same station at the same time.

c. Progressive die (also known as continuous die) has two or more stations in the feeding direction of the blank. In one stroke of the press, it is a die that completes two or more stamping processes at different stations one by one.

d. The transfer die integrates the characteristics of single process die and progressive die. By using the manipulator transfer system, the product can be quickly transferred within the die, which can greatly improve the production efficiency of the product, reduce the production cost of the product, save the material cost, and have stable and reliable quality. -

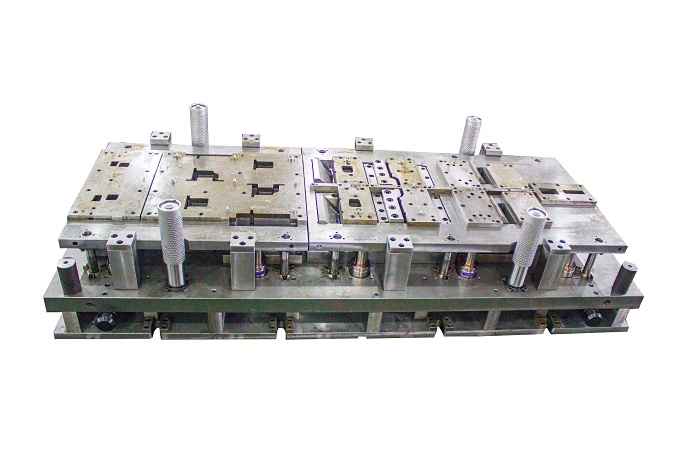

Stamping Compound Mould

We have large-scale precision CNC and multiple presses to meet the mold test and production needs of various sizes of molds. With high precision, fast processing and accurate molding, we pursue customer satisfaction and help customers achieve exquisite quality. Through the optimization of processing technology and the popularization of automatic programming, the production and processing efficiency is effectively improved. The strict quality control system and high-efficiency working team have rich design experience and mold manufacturing experience.

Send Email Details -

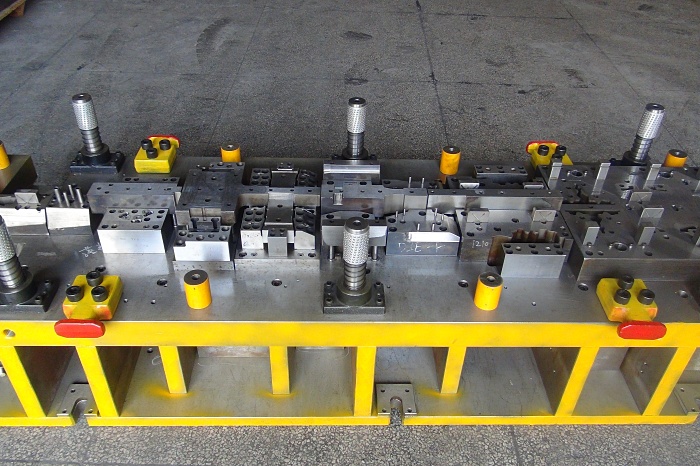

High Speed Stamping Mould

We have large-scale precision CNC and multiple presses to meet the mold test and production needs of various sizes of molds. With high precision, fast processing and accurate molding, we pursue customer satisfaction and help customers achieve exquisite quality. Through the optimization of processing technology and the popularization of automatic programming, the production and processing efficiency is effectively improved. The strict quality control system and high-efficiency working team have rich design experience and mold manufacturing experience.

Send Email Details -

Mould Stamping Parts

We have large-scale precision CNC and multiple presses to meet the mold test and production needs of various sizes of molds. With high precision, fast processing and accurate molding, we pursue customer satisfaction and help customers achieve exquisite quality. Through the optimization of processing technology and the popularization of automatic programming, the production and processing efficiency is effectively improved. The strict quality control system and high-efficiency working team have rich design experience and mold manufacturing experience.

Send Email Details -

Stamping Process Mould

Stamping die classification:

Send Email Details

a. Single process die is a die that only completes one stamping process in one stroke of the press.

b. The compound die has only one station. In one stroke of the press, two or more stamping processes are completed at the same station at the same time.

c. Progressive die (also known as continuous die) has two or more stations in the feeding direction of the blank. In one stroke of the press, it is a die that completes two or more stamping processes at different stations one by one.

d. The transfer die integrates the characteristics of single process die and progressive die. By using the manipulator transfer system, the product can be quickly transferred within the die, which can greatly improve the production efficiency of the product, reduce the production cost of the product, save the material cost, and have stable and reliable quality. -

Stamping Mold

The material for manufacturing the mold shall have high hardness, high strength, high wear resistance, appropriate toughness, high hardenability, no deformation (or little deformation) during heat treatment and no cracking during quenching.

Send Email Details

Reasonable selection of die materials and correct heat treatment process are the keys to ensure die life. For molds with different uses, comprehensive consideration shall be made according to their working conditions, stress conditions, properties of processed materials, production batch and productivity, with emphasis on the above-mentioned properties, and then corresponding selection of steel type and heat treatment process shall be made.