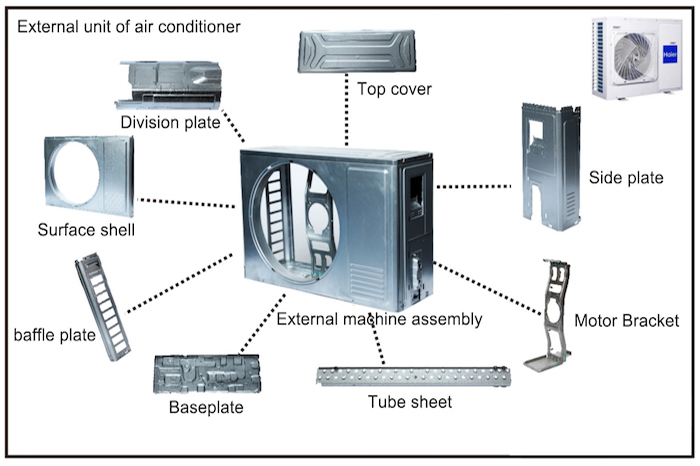

Manufacturer of precision metal stamping parts

Suzhou nexttool Automobile Technology Co., Ltd., the predecessor of Suzhou Boying precision mould Co., Ltd., was founded in 2006, with a total investment of 220 million yuan and an annual output value of 110 million yuan. At present, the company has its own land of 30 mu and a building area of more than 22000 square meters. The company has the independent mold development ability, and is a key enterprise in the whole process from mold development to stamping production, welding and riveting.

-

25-08-2022

The scratches on the surface of precision metal stamping parts are mainly due to the relative movement between the workpiece and the mold surface. Under the action of a certain pressure, the blank and the local surface of the mold directly generate friction. In addition, the deformation heat of the blank causes the blank and metal chips to deposit on the mold surface, and the scratch on the surface of the workpiece.

-

25-08-2022

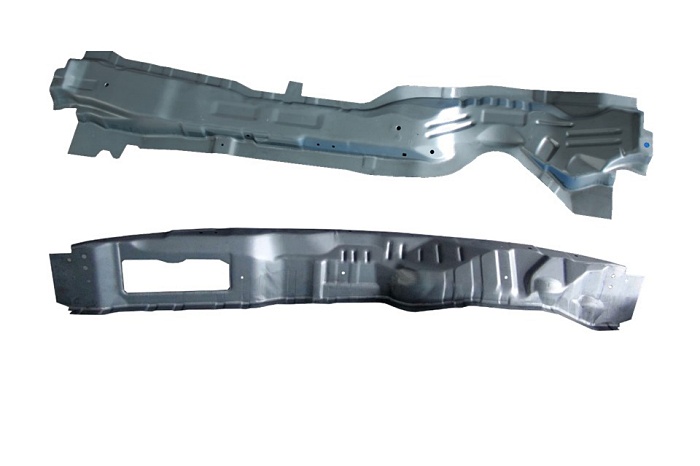

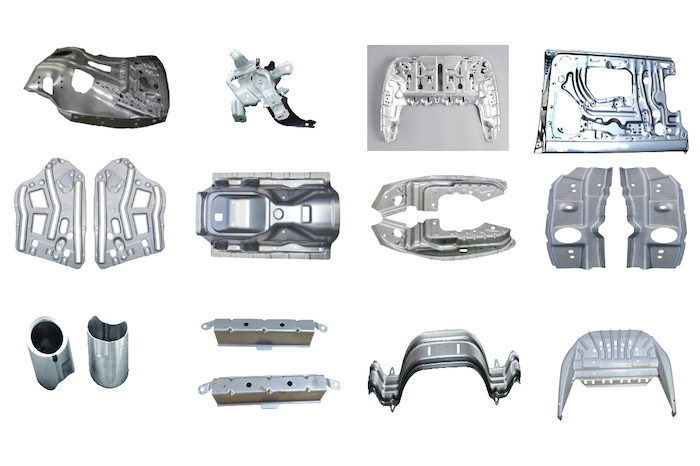

Automotive precision stamping parts are metal stamping products used in automobiles. Supports, end covers, covers, spring seats, dust covers, etc. belong to automotive precision stamping parts, with a wide variety of products, and high requirements for surface quality, rigidity and dimensional accuracy.

-

25-08-2022

In the steel plate specification category, whether it is fixed length plate or coiled plate, the same material and material thickness have different coil widths and different sales prices. Therefore, in order to reduce the cost, it is necessary to work hard on the formulation of the procurement roll width, and try to select the roll width range without price increase on the premise of ensuring the material utilization rate.

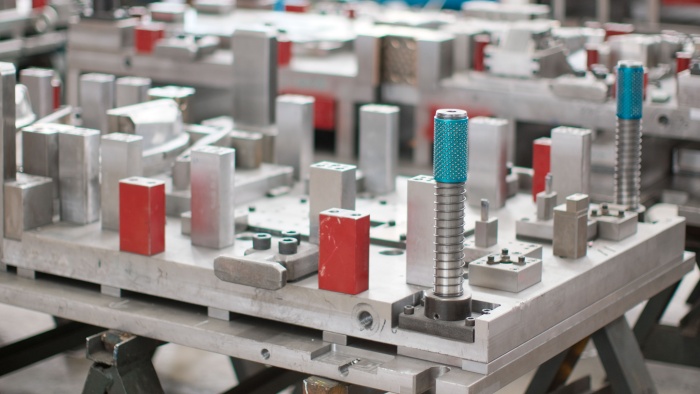

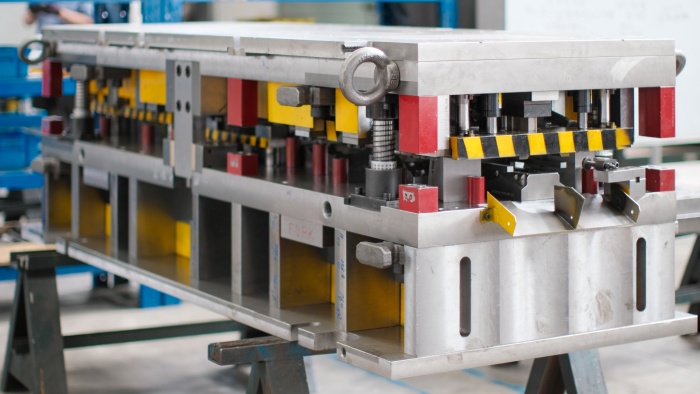

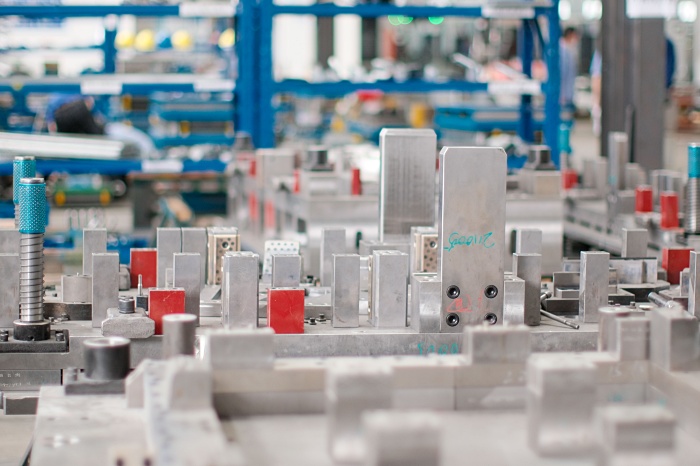

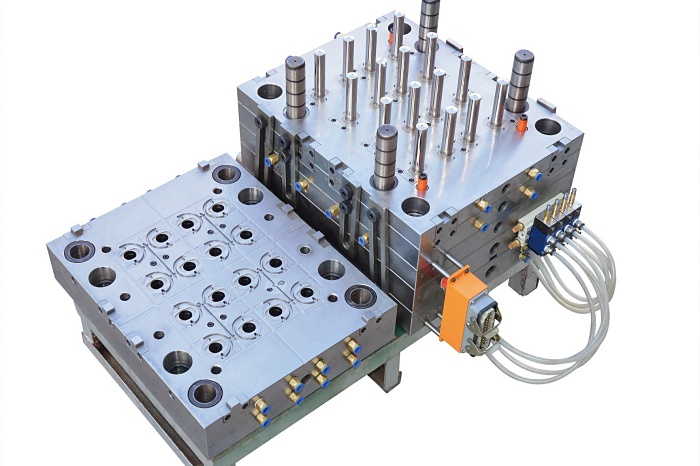

Stamping Mould Processing

Hot Stamping Mould

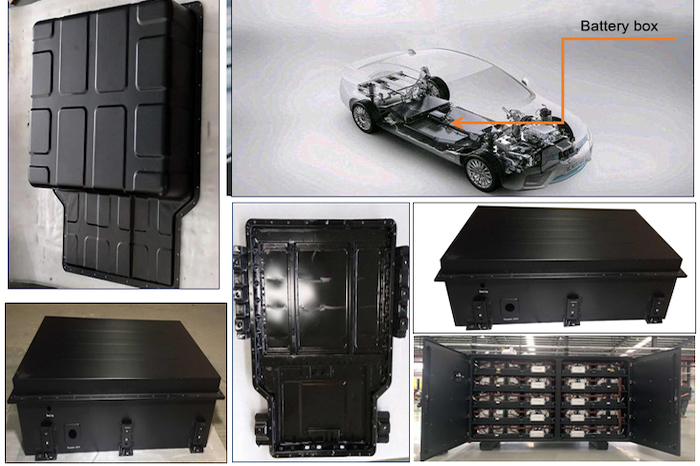

New Energy Battery Pack

Large Continuous Mode

Aluminum Alloy Die Casting

Sheet Metal Stamping Mould

Sheet Metal Mold

Punching Of Sheet Metal Parts

Sheet Metal Box

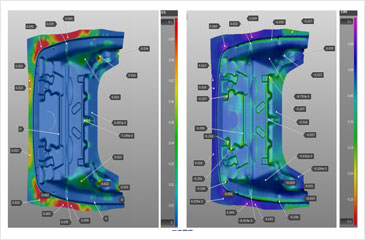

Stamping Mould For Automobile High Strength Plate

Magnesium Alloy Die Casting

Automobile Sheet Metal Parts

High Strength Plate Stamping Mould

Stamping Mould Automobile

Automobile Battery Box

Sheet Metal Stud

Sheet Metal Shell

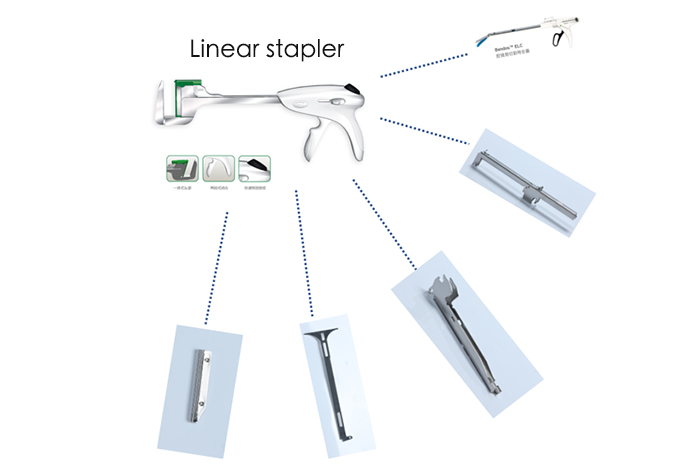

Medical Sheet Metal Parts

Plastic Spraying Of Sheet Metal Parts

Automobile High Strength Plate Stamping