sheet metal mold

-

Sheet Metal Mold

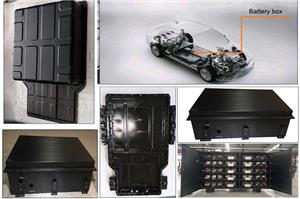

The stamping part is a forming and processing method that applies external force to the plate, strip, pipe and profile by the press and die to produce plastic deformation or separation, so as to obtain the workpiece (stamping part) with the required shape and size. Stamping and forging belong to plastic processing (or pressure processing) and are collectively referred to as forging. The stamping blanks are mainly hot-rolled and cold-rolled steel plates and strips. At present, our factory has a total of 40 small, medium and large punches and three laser cutting machines, which can produce various continuous dies and single punch dies. Metal deep drawing is to use stamping, pull ring or metal die to deform sheet metal materials into cylindrical or box shaped parts. Deep drawing is usually carried out on the anti wrinkle pressing plate of the double action press. The anti wrinkle pressing plate can effectively prevent the raised edge from wrinkling when it is pulled into the steel mold. Deep drawing technology is widely used in the production process. Deep drawing is applied in many industries. For example, it can be used to produce automobile parts in the automobile industry and also to manufacture household products.

Email Details